Introduction to High-Precision Gear Reducer

The High-Precision Gear Reducer plays a crucial role in enhancing the performance and efficiency of modern machinery. By converting input speed into controlled output speed while maintaining high accuracy, these reducers are essential for robotics, automation, and industrial equipment.

- Improved efficiency and torque transmission

- Enhanced operational precision

- Reduced mechanical backlash

Types of High-Precision Gear Reducer

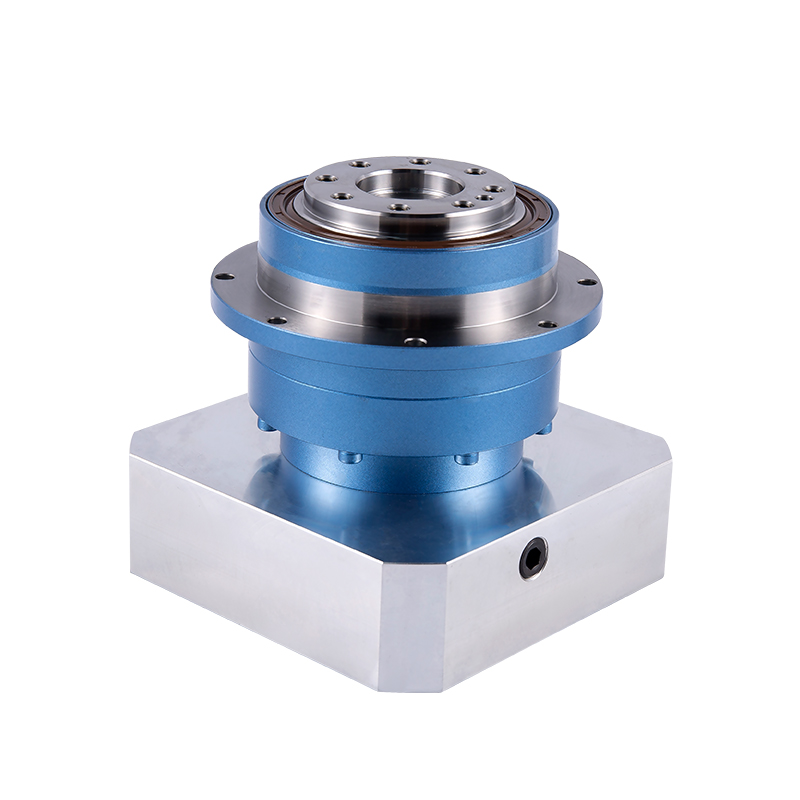

High-Precision Planetary Gear Reducer for Robotics

- Compact structure suitable for robotic joints

- High torque density for precise movement

- Reliable in repetitive motion applications

| Feature | Planetary Reducer |

| Torque | High |

| Precision | ±0.01° |

| Application | Robotics |

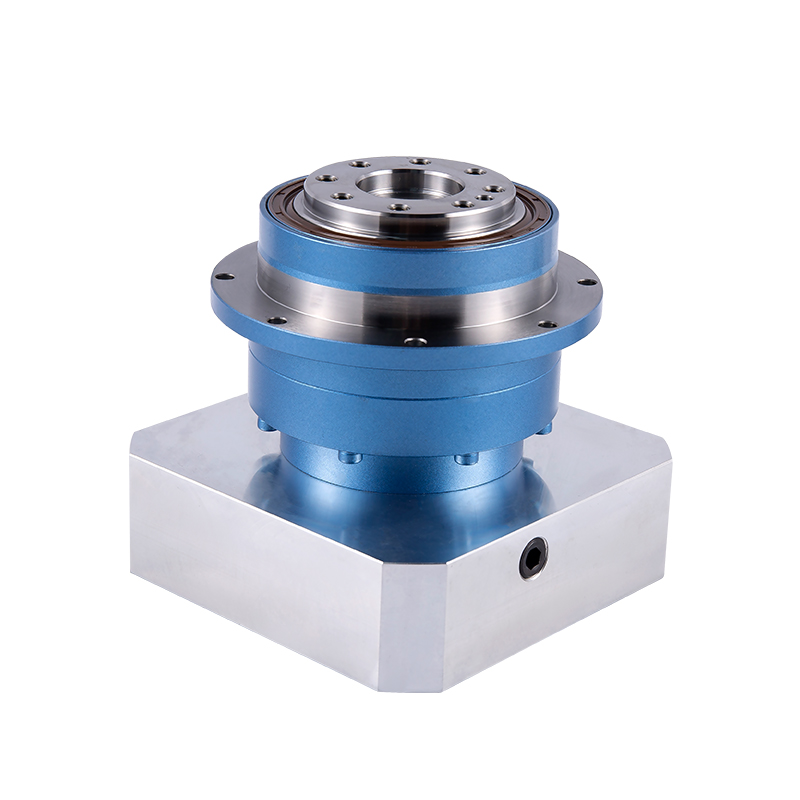

Compact High-Precision Gear Reducer for Automation

- Space-saving design ideal for automated machinery

- Energy-efficient operation

- Versatile integration in conveyor and assembly lines

| Metric | Value |

| Size | Compact |

| Efficiency | 95% |

| Application | Automation Systems |

High-Precision Worm Gear Reducer Applications

- Suitable for high torque and low-speed operations

- Used in heavy-duty industrial machinery

- Offers smooth motion control

| Type | Worm Gear | Planetary Gear |

| Torque | Medium-High | High |

| Precision | ±0.05° | ±0.01° |

| Application | Industrial | Robotics |

Low-Backlash High-Precision Gear Reducer

- Minimizes backlash for high-precision tasks

- Essential in CNC machines and robotics

| Reducer Type | Backlash (°) |

| Standard | 0.05 |

| Low-Backlash | 0.01 |

Durable High-Precision Gear Reducer for Industrial Equipment

- Long service life and minimal maintenance

- High resistance to wear and tear

| Reducer Type | Durability (Years) |

| Standard | 5-7 |

| Durable | 10 |

BEITTO's Expertise in High-Precision Gear Reducer

- Specialized in high-precision planetary reducers

- Adopts Japanese R&D and meticulous production technology

- Located in Pinghu City, Zhejiang Province – strategic industrial base

- Focus on product optimization and structural upgrades

Selecting the Right High-Precision Gear Reducer

When choosing a High-Precision Gear Reducer , key factors include torque capacity, precision, size, and durability. Matching the reducer to your application ensures optimal performance and long-term reliability.

| Reducer Type | Torque | Precision | Size | Durability |

| Planetary | High | ±0.01° | Compact | 8-10 Years |

| Worm Gear | Medium-High | ±0.05° | Medium | 7-9 Years |

| Low-Backlash | High | 0.01° | Medium | 8-10 Years |

Conclusion

The High-Precision Gear Reducer enhances efficiency, accuracy, and reliability in various applications, from robotics to industrial machinery. BEITTO, with its advanced Japanese technology and strategic location in Pinghu City, provides cutting-edge solutions for demanding industries.

FAQ

- Q1: What is the main advantage of a High-Precision Gear Reducer ?

A1: It ensures high accuracy, reduced backlash, and improved torque transmission. - Q2: Where is BEITTO located?

A2: In Pinghu City, Zhejiang Province, China. - Q3: Which reducer is best for robotics?

A3: High-Precision Planetary Gear Reducer for Robotics . - Q4: How to select the right gear reducer?

A4: Consider torque, precision, size, and durability for the intended application. - Q5: What makes BEITTO's reducers unique?

A5: Advanced Japanese R&D, meticulous production process, and continuous product optimization.